2012

|

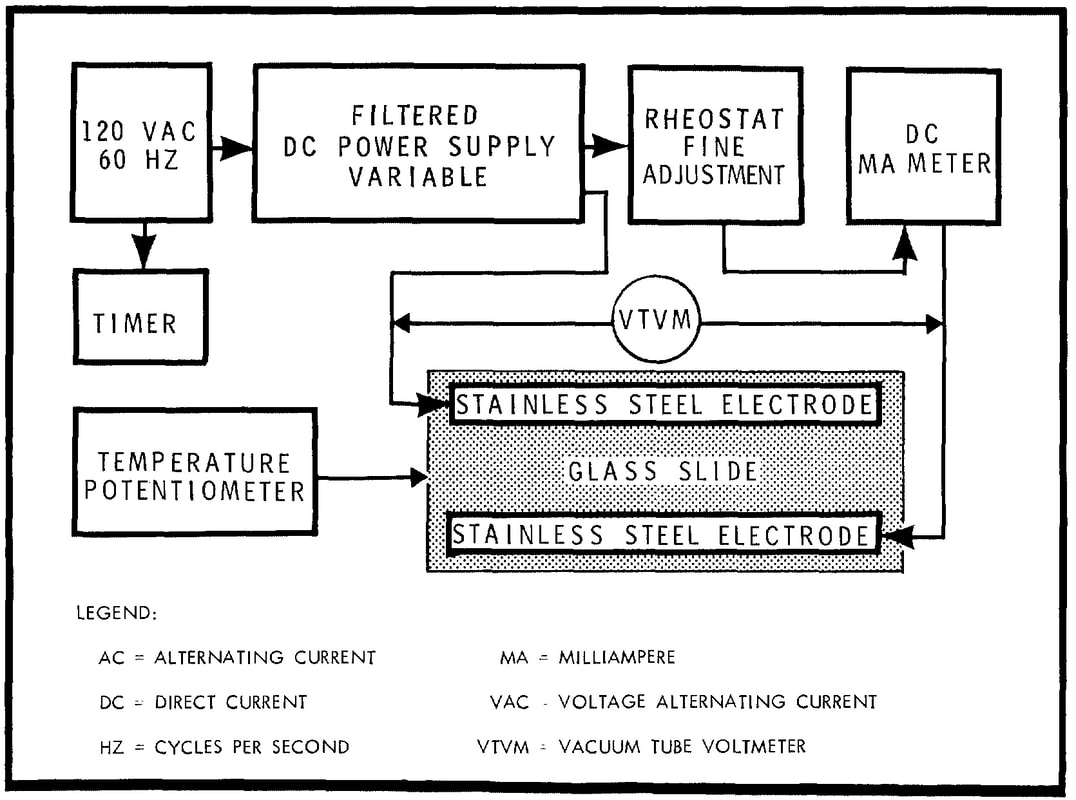

Nematologist and Lisi Global cofounder Dr. Ekaterini Riga, was using a patch amplifier to measure the neurological responses of nematodes for an ongoing electrophysiology study, but for some reason the subject nematodes were dying when she turned on the amplifier. She'd done this procedure hundreds of times, something was wrong. Electrical Engineer and Lisi co-founder, Jason Crisp, was able to troubleshoot the equipment and discovered a small amount of stray voltage was electrocuting the nematodes. He fixed the amplifier but that wasn't the end of it.

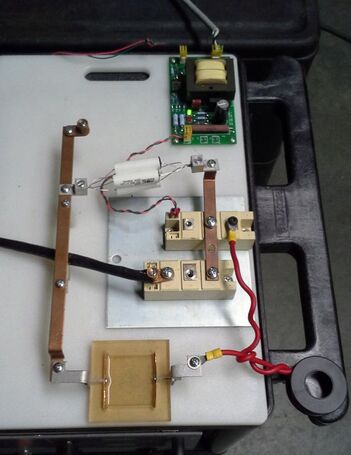

The episode nagged at Jason. Nematodes are extremely resilient... but that tiny bit of electricity definitely killed those nematodes. "Is that all it takes?" he thought. A bit of research confirmed that this had been proven decades ago on a similarly small scale. Jason did the math and quickly figured out why no one had tried to do it on a large scale. Those experiments happened in the early '70's, the technology to manage that kind of energy applied to the soil didn't exist. But, "It exists now." Jason said. At the time, Jason and third cofounder Jeffery McComb were business partners in a medical imaging equipment company. Using parts from decommissioned x-ray equipment, they could scale the earlier experiment 20x's with what they had on the shelf. Jason borrowed a 3000 watt sound amplifier from his buddy's Pink Floyd tribute band and the team tested the rudimentary circuit. It was a success! All the nematodes exposed to the electric field in the test cell died. |

2013It worked, now what? We had a steep learning curve to scale the technology from a 20cc test cell of water to just a medium-sized pot of soil. Acquiring components was the challenge to treating larger volumes, and we needed a lot more power. We found a used 4kW power supply (PS) on Ebay that would be the foundation of two versions of the DES. Each one more complex than the last and capable of treating larger volumes of soil. There was one problem, we didn't have access to 3-phase power for the power supply. We approached Scott Gorham, a Richland machinist who cleared out a corner of his shop where we could set up our equipment. Scott built the various test cells and delivery apparatus for us, whatever we needed he was happy to help. We performed hundreds of treatments, even trying it on grubs and crickets and each batch of results raised more questions.

We'd shown that the technology worked and that we could scale it. A non-chemical solution to nematode infestations that ravages global crop yields is a big deal! So, what do we call ourselves? After much discussion about a company name (nothing with “solutions”, at the behest of cofounder, Jeffery McComb) the team agreed on ‘Lisi Global’, Lisi means ‘solutions’ in Greek. Dr. Riga, who is Greek, will tell you that the Greeks invented humor. |

This is a critically important breakthrough in non-chemical soil pest control with the potential to revolutionize not just nematode management but that of soil pest and pathogen infestations in many different cropping systems and environments. |

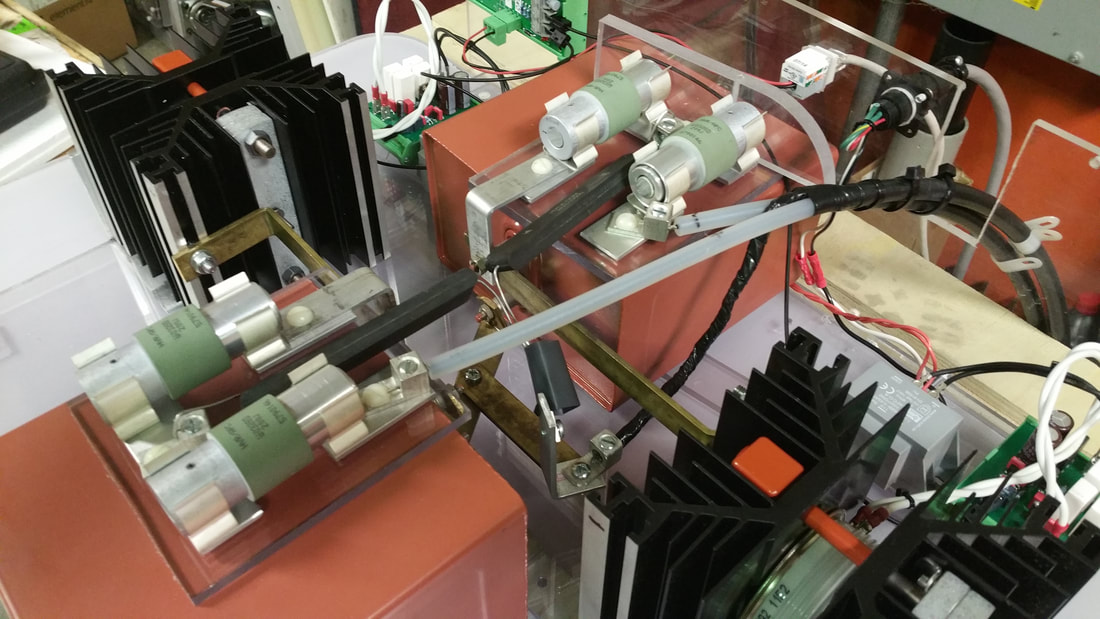

2014By the end of 2013, we had maxed-out the capabilities of our 4kW circuit architecture and there was still A LOT to learn. We needed more power to scale up treatment volumes. We got lucky finding the first power supply on Ebay, but the next jump meant a custom piece so we commissioned a sister PS from TDK Lambda, the company that built the one we had. Using the two PS together would double the output to 8kW.

Available power was only half the challenge. None of the parts we had would scale; we needed different components to handle the additional power. Like the PS, we had to purchase all new components and get them flying formation. It would take nearly six months to acquire all the pieces to build the DES 3.0. Russian capacitors by way of Finland, solid-state high voltage switches from Germany, control circuitry from Bulgaria; we tested the circuit and tested it again, THEN..... we broke it. A high voltage measurement probe failed - which resulted in damage to our brand new power supply. It was very loud. |

We returned the PS to the manufacturer who noted that the damage caused by the voltage reversal would not be covered under warranty. This seemed obvious to us but we appreciated the diligence. When we got the repaired PS back there was a new sticker applied to the cover that warned us specifically of the damage that could occur in the event of a voltage reversal. We laughed. This was obvious to say the least. To be sure, Jason designed a protection circuit to prevent another voltage reversal event from causing any more havoc and we were ready to take the DES 3.0 on the road.

|

2015We started working with USDA ARS nematologist Inga Zasada at Oregon State University in 2014, she provided infested soil that we could treat and then return for analysis. It was during these trials when we discovered that the amount of energy applied tracked linearly with the level of nematode control observed. In Spring of 2015, we took the DES 3.0 to Corvallis to treat fallow soil and, for the first time, planted soil to determine if our technology would kill the plant or save it from infestation.

What we learned in those early greenhouse trials was a game-changer for Lisi Global. Not only was the plant unaffected by the energy, having the plant in place actually made the treatment MORE effective. Treating established plants that had yield-limiting nematode infestations meant we could reduce the frequency of replants for small berry fruits, orchards, and other long-standing crops. Before the end of the year we performed trials on turf and on raspberry canes, two high-value, small area crops that struggle to control nematodes. The results of these trials weren't dramatic, but we were learning about the energy we needed to deliver an effective treatment. |

2016 - 2017We had a pretty good run of successful trials in 2015, so successful that our research collaborators made us repeat all of them in 2016. The consistency in the data was not anything they were used to seeing so we needed to confirm our results. We also began tailoring the energy profile to target fungal pathogens. The success of these trials was surprising given the limited amount of energy available and the hardy fungi selected to really test DES capabilities. "No detectible inoculum", words the mycologist had never written before. Seemed we were on to something there as well.

We started taking the DES into the field, maxing out the capabilities of the technology and learning as much as we could using what we had. It was apparent that we needed to scale this technology even further but it would have to be designed and built by an outside firm that specializes in pulsed power systems. Little did we realize the challenge this presented. |

2018 - 2019We'd talked to hundreds of growers and researchers about Lisi Global and DES over the years, so we knew we had something unique; a true game-changer for countless ag industries. It was time to scale the technology and grow our business. We were finally granted our first patent in 2018. That, combined with a solid business model and we felt like we were ready to take on investors.

Up to this point, Lisi Global had been bootstrapped with loans from the medical imaging company. We were going to need a lot more money to take Lisi to the next level so we began developing our business plan and pitch deck for investors. By the end of 2018 we had converted to a C-corp and secured more than $100k of convertible note investment. Also, with the help of consultant Bryan Brewer, we had a professional business plan, pitch deck and financial projections ready to present to potential investors. With Bryan's guidance, 2019 was the year of pitching to investors. Focusing on the Seattle VC scene, Jason pitched to more than a dozen groups, telling the story of Lisi Global's unique technology. We were always received well as a sustainable solution to a global problem, a journey that culminated at the Bend Venture Conference where Lisi was a finalist among early stage startups. Although none of the pitch opportunities resulted in investment, we did secure another $200k in convertible note investment from "friends and family." At the end of 2019, we made a critical introduction to Georgios Chrysanthakopoulos and the team at Directed Machines. Based in Seattle, Directed Machines develops and deploys autonomous tractors designed to perform maintenance duties like mowing or snow removal on a medium scale. Think: subsistence farm. The size of the tractor was perfect for our turf application, it was battery powered and solar recharged, it had a suite of GPS and monitoring electronics that would interface beautifully with the DES and it's unique parameters. In that moment, as we watched Georgios put the robot through it's paces, we committed to moving the DES from power generated by fossil fuel to battery power. It was a pivotal event in the development of the DES. |

2020We were on a roll! Jason, Jeff and Conan Doherty, Lisi's first hire, ventured to Orlando for the Golf Industry Show to meet with the first Direct|Turf distributor, Rob Dillinger of MD Plant Health. Q1 2020 saw a steady flow of F&F investment that propelled the build of the first full-scale electronics package, the DES 4.0, with technology partner ARRS Technologies in San Diego. The 4.0 would validate our greenhouse results in golf turf, our initial target market for DES. Conan, meanwhile, did what he does best, leveraging relationships to secure investment and deployment opportunities for the 4.0. We were prepared for a busy and, hopefully, profitable 2020.

Not so fast... Like everyone, the initial uncertainty of the Covid-19 crisis stopped us in our tracks. Investment dried up and we resigned ourselves to maintaining the status quo for the foreseeable future. Miraculously, things started picking up almost as fast as they stopped. In May, investment started flowing again and by Q3 we had to up the cap on our convertible note to accommodate the additional investment. Even though we were in lock down, we still made progress. We finished development of the Directed Energy soil amendment brands, thanks to Think Tanky Consulting. We repackaged the DES 3.0 to make it more suitable to transport on the Directed Machines robot that we had picked up in March. Jason had time to dive into the battery technology we would need to power the DES, answering some tough questions about how much stored energy we would need. We also performed numerous bench top trials in the shop to keep the data flowing. In June, Conan connected with Mark Mahady, a turf grass researcher based in California. Mark has managed trials at the research green at The Links at Spanish Bay on the Monterey Peninsula for a decade. Typically, the trials book-out with chemical companies testing their latest product but Covid forced several to pull back their research budgets. This left room for Lisi Global in the summer, 2020 trial. Despite a number of challenges and setbacks, we completed the six-month trial, showcasing DES's efficacy on three types of nematodes. We came away with some solid results and more than a few advocates among the course supers on the Peninsula. |

|

2021It took more than two years to develop and build the DES 4.0 and turf treatment apparatus but in July, 2021 we introduced Direct|Turf to the our friends on the Monterey Peninsula, returning as promised to demonstrate the real potential of Directed Energy Technology. Trial runs on greens at Spanish Bay and the prestigious Monterey Peninsula Country Club were the first full scale demonstration of DES capabilities as a non-chemical soil pest control technology and ultimate validation of 10 years of effort.

Turf is an important traction channel for DE Technology where we can develop and refine energy profiles with very short data collection cycles. Development of DE technology is grounded in the idea that by reducing the impact of harmful soil pests, the technology can increase crop yield, increases that could change the world. We see DE technology as an important weapon in the battle for global food security. It can be adapted for application to nearly every cropping system on the planet. While we focus on effective, efficient energy profiles for turf, we will use that data to inform applications in small berry fruit and wine grapes, and eventually row vegetables and large area crops across the US. What we learn we will deploy in Europe, South America, Africa and beyond, to increase crop yields that have a direct impact on global food security. "Global" is in our name because we knew from the very beginning that DE technology has the potential to change the world. |

|

|

2022 and Beyond |

Weed ControlThrough a series of events, Lisi contracted with one major rail company in the U.S. to support their R&D efforts in controlling weeds along railways.

|

Hops Fields in Washington StateLisi is working with top ag researchers and local hops farmers in central Washington, adapting our technology to support increase crop yields.

|